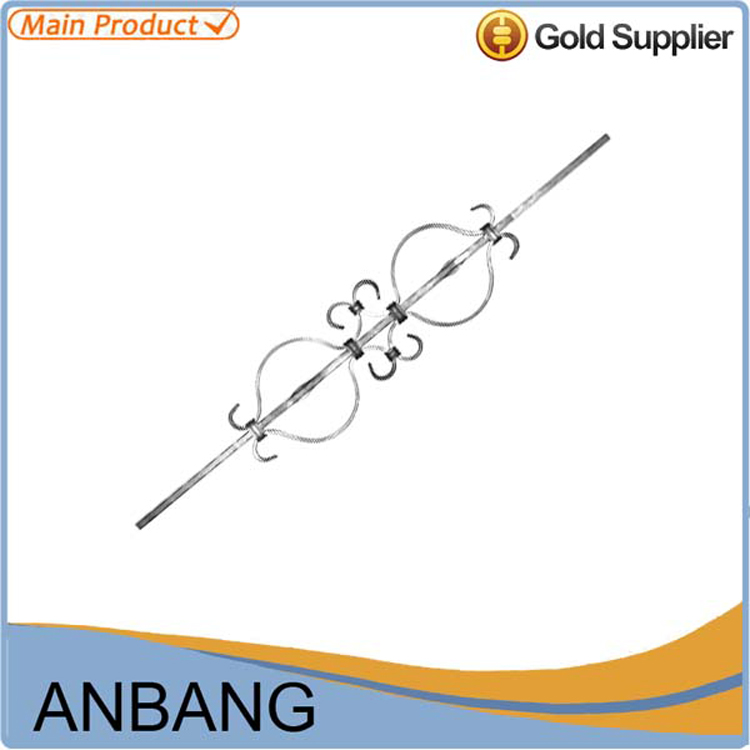

WROUGHT IRON FORGED BAR/CODE:3381

Iron forging is a metal processing process that uses high temperature and pressure to make metal materials undergo forging, stretching, bending, and other operations, changing their shape and characteristics to meet design requirements. Iron forging usually uses iron materials, such as iron plates, pipes, and bars.

The process of iron forging includes the following steps:

Design and develop forging plans: Determine the required forging process, materials, and equipment based on product requirements and design drawings.

Heating metal materials: Use a forging furnace to heat the metal materials to a suitable temperature, improving their plasticity.

Forging operation: Put the heated metal material into the forging equipment, and use tools such as a forging hammer or hydraulic press to hammer, compress, and stretch the metal material through impact or continuous deformation, so as to change its shape.

Adjustment and coordination: During the forging process, adjust and coordinate the shape and characteristics of metal materials as needed.

Cooling and treatment: Cooling and treating the forged metal material to stabilize and solidify it, achieving the required physical properties.

Carving and decoration: According to needs, the forged metal products can be decorated with carving, painting, spraying, and other decorative treatments.